Our company prides itself on its exceptional capability in product structure design for die casting products. With a team of skilled engineers and designers, we possess the expertise to create innovative and efficient product structures that maximize functionality and durability.

When it comes to die casting products, it is crucial to strike the right balance between design complexity and manufacturing feasibility. Our team combines industry knowledge with the latest design software to ensure that the product structure meets both performance requirements and manufacturing constraints.

We begin the product structure design process by thoroughly understanding the client's needs and specifications. Our engineers collaborate closely with the clients to gather all the necessary information, such as desired functionality, target market, and any specific design preferences. This helps us create a clear vision for the product and establish design goals.

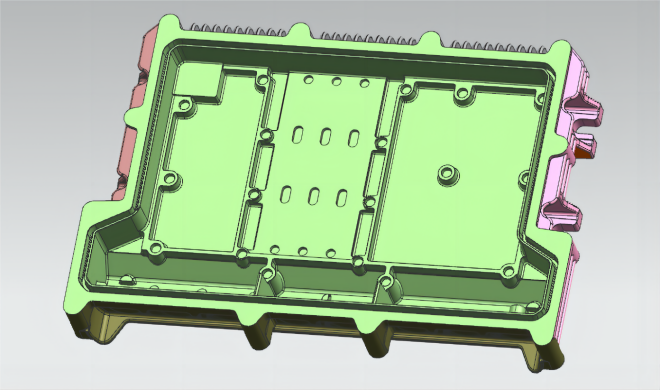

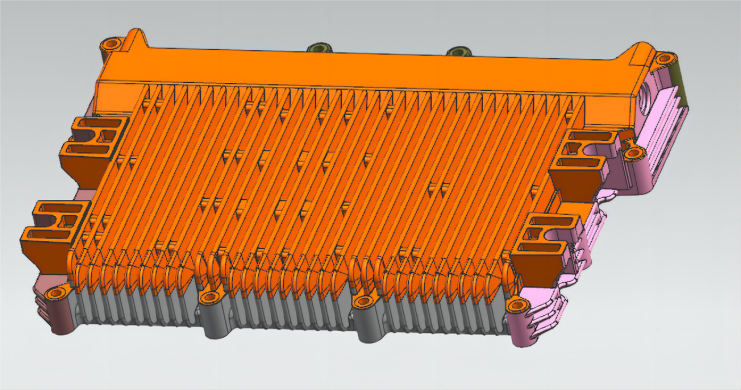

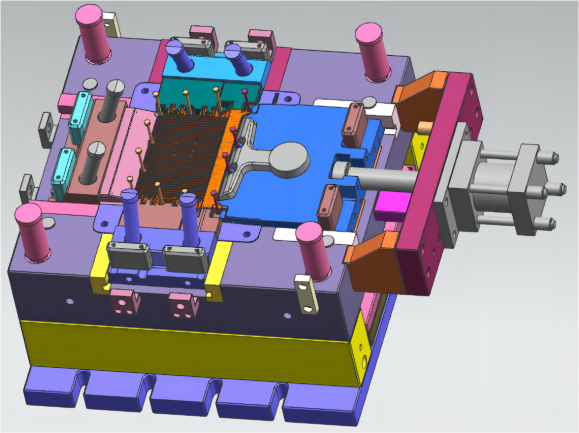

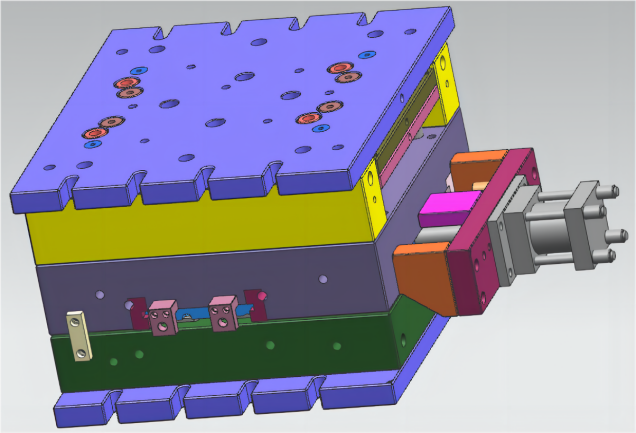

Using advanced computer-aided design (CAD) software, we develop 3D models of the product structure. This allows us to visualize and evaluate the design from various angles, ensuring that it meets all functional and aesthetic requirements. Our team carefully considers factors such as material selection, structural integrity, weight optimization, and ease of manufacturing during the design process.

To ensure the manufacturability of the die casting product, we conduct thorough design reviews and feasibility studies. This involves analyzing the design for potential casting defects, such as porosity or shrinkage, and making necessary design modifications to mitigate these issues. Our goal is to create a product structure that not only performs well but can also be efficiently produced using the die casting process.

Through our expertise in product structure design for die casting products, we have successfully developed a wide range of components for various industries. Our commitment to excellence and attention to detail set us apart, allowing us to deliver superior-quality products that meet and exceed our clients' expectations.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP