The MES (Manufacturing Execution System) management system is a comprehensive software solution designed to monitor, control, and manage manufacturing processes on the factory floor.

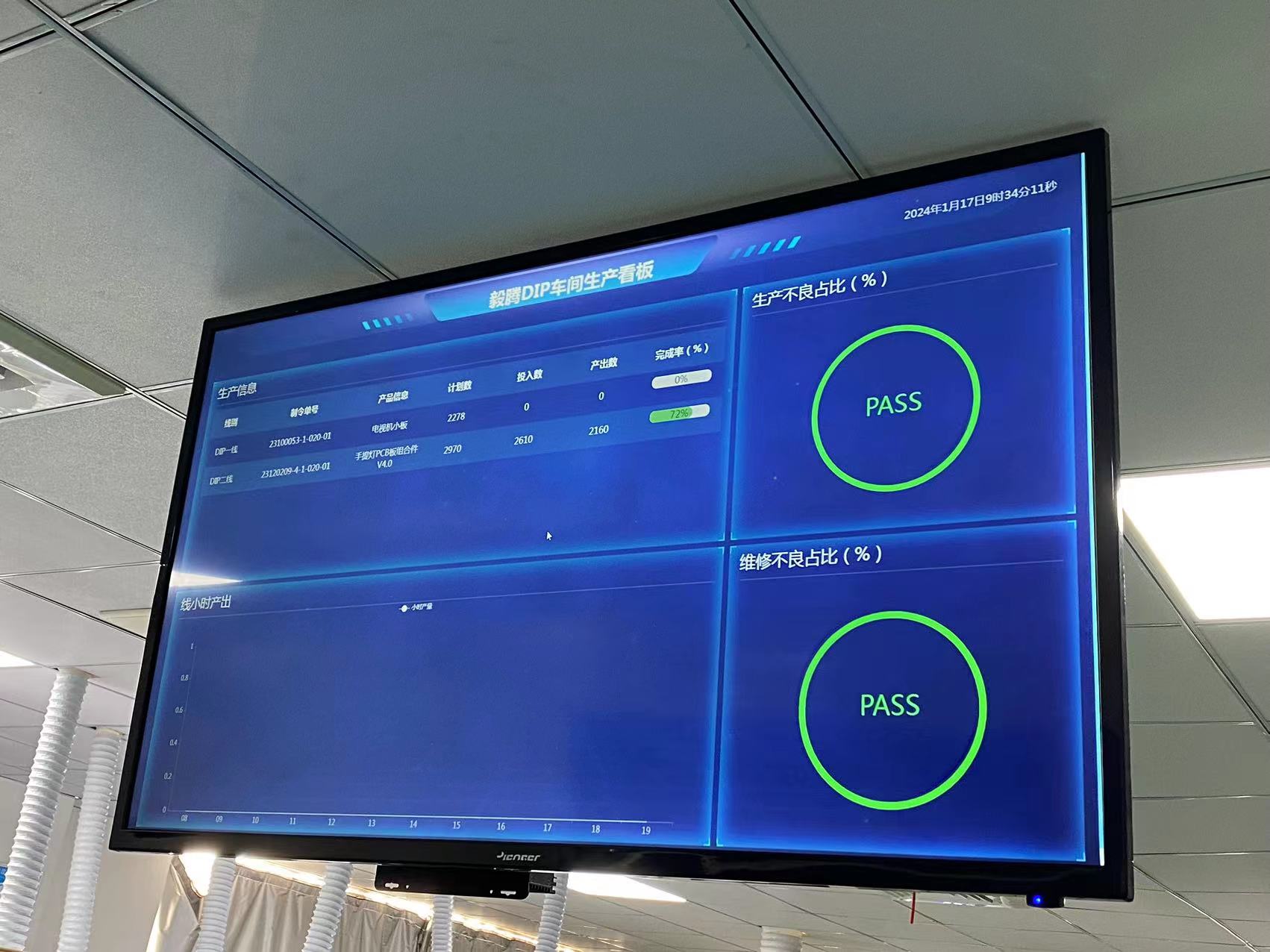

It serves as a bridge between the enterprise resource planning (ERP) system and the automation systems on the shop floor, providing real-time visibility into the production process.

One of the key benefits of introducing an MES management system is the optimization of production processes. By integrating data from various sources such as machines, sensors, and manual inputs, the system provides a holistic view of the manufacturing operations. This enables better decision-making, improved resource utilization, and enhanced overall efficiency.

Additionally, MES systems facilitate traceability, allowing for the tracking of materials, work in progress, and finished goods, leading to better inventory management and able to track the material sources.

The system is important for our company for several reasons:

Firstly, it helps us meet the increasing demands for product quality, traceability, and compliance. With stringent regulations and customer expectations, having a robust MES management system in place ensures that we can consistently deliver high-quality products while adhering to industry standards.

Secondly, the system enhances our ability to respond to changes in demand and adapt to dynamic market conditions. Real-time data and analytics provided by the MES system enable us to make agile decisions and adjust production schedules as needed.

Finally, the system fosters a culture of continuous improvement by providing insights into operational performance, identifying bottlenecks, and supporting root-cause analysis, thereby driving operational excellence and innovation.

The MES management system is a pivotal tool for modern manufacturing operations. Its ability to streamline processes, improve efficiency, ensure quality, and facilitate agility makes it an indispensable asset for our organization's competitiveness and long-term success.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP