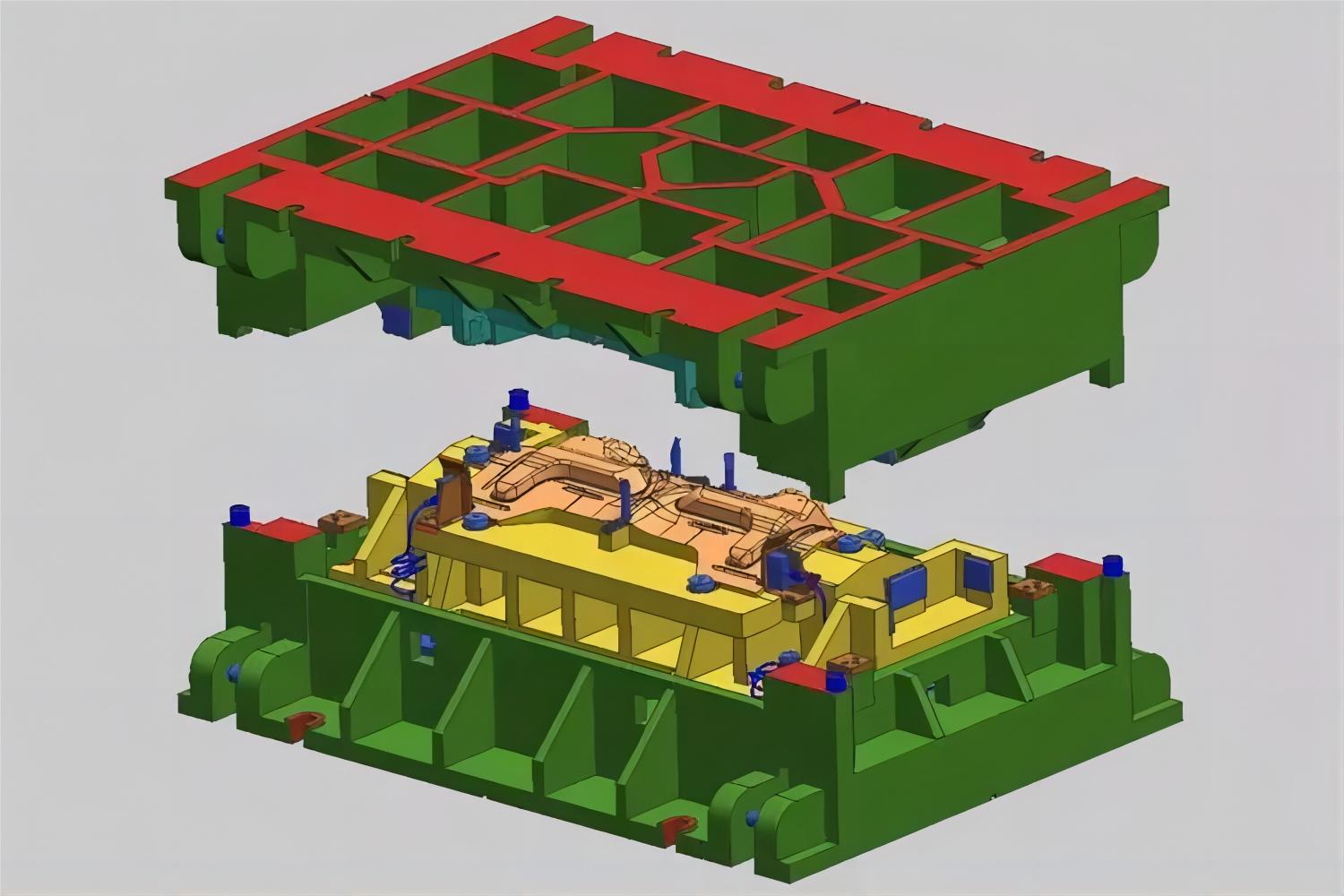

Sheet metal stamping dies are essential tools in the sheet metal fabrication process. They enable precise processing of metal sheets into the desired shapes and sizes. The design of stamping dies is crucial for achieving efficient and accurate processing.

The process of designing sheet metal stamping dies includes several key steps:

1. Product analysis: Before designing the stamping dies, a comprehensive analysis of the sheet metal product to be processed is conducted. This includes considerations of the product's shape, dimensions, material, and processing requirements. Through product analysis, the required stamping processes and die structures can be determined.

2. Die structure design: The design of the stamping die structure is critical for achieving processing accuracy and efficiency. Factors such as cutting forces, cutting speeds, and die stability need to be considered during the design process. Additionally, it is important to design appropriate guiding, positioning, and clamping devices to ensure precise die positioning and stable processing.

3. Material selection: The choice of materials for stamping dies directly impacts their lifespan and processing quality. Common materials for stamping dies include tool steel, hard alloys, and high-speed steel. Selecting the appropriate material based on specific processing requirements and expected die lifespan is crucial.

The key to successful sheet metal stamping die design lies in considering product requirements, processing techniques, and die structures to achieve efficient and precise processing. A well-designed stamping die can improve production efficiency, reduce costs, and ensure product quality and consistency.

As a professional sheet metal fabrication factory, we have an experienced design team and advanced manufacturing equipment to provide high-quality sheet metal stamping die design and manufacturing services. We are committed to offering customized solutions to meet the needs of various industries.

If you have any further questions or requirements regarding sheet metal stamping die design or other sheet metal fabrication aspects, please feel free to contact us. We are dedicated to providing you with professional services and support.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP