Search

The Advantages of Aluminum Die Casting: A Comprehensive Guide

- Oct 16,2023

-

Share

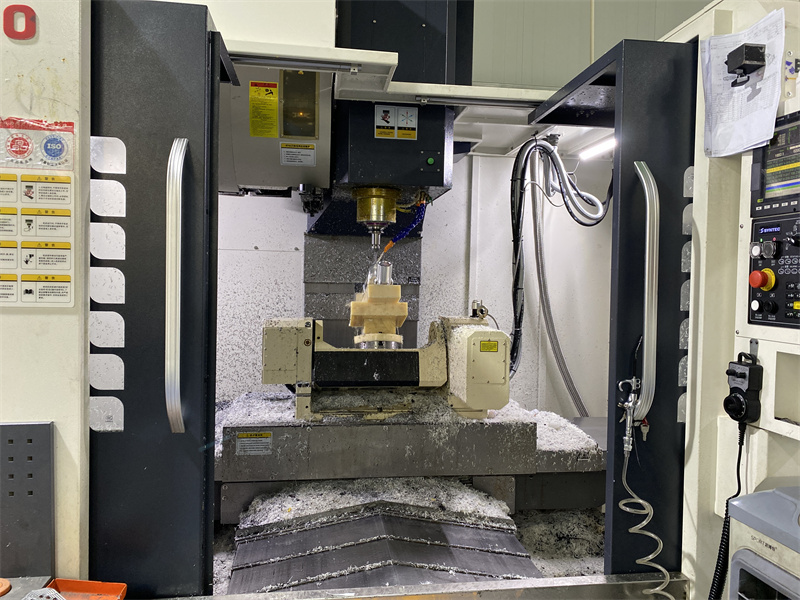

Aluminum die casting is a widely used manufacturing process that offers numerous advantages. One of the key benefits of aluminum die casting is its lightweight nature. Aluminum is about one-third the weight of steel, making it ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

In addition to being lightweight, aluminum die casting also possesses a high strength-to-weight ratio. This means that despite its lightness, aluminum can still provide exceptional strength and durability. This characteristic makes it suitable for producing complex and intricate parts that require both strength and precision.

Another advantage of aluminum die casting is its excellent thermal conductivity. Aluminum efficiently dissipates heat, making it an ideal choice for components that require effective heat management, such as heat sinks in electronic devices. Its superior thermal conductivity helps prevent overheating and ensures optimal performance.

Furthermore, aluminum die casting offers excellent corrosion resistance. Aluminum naturally forms a protective oxide layer, which helps protect the metal from corrosion. This makes it suitable for applications in harsh environments or those exposed to moisture, such as marine equipment or outdoor lighting fixtures.

Moreover, aluminum die casting provides design flexibility and cost-effectiveness. The die casting process allows for the production of complex shapes with tight tolerances, reducing the need for additional machining operations. This results in cost savings and faster production times.

In conclusion, aluminum die casting offers a range of advantages, including lightweight construction, high strength-to-weight ratio, excellent thermal conductivity, corrosion resistance, design flexibility, and cost-effectiveness. These benefits make it a preferred choice for various industries, enabling the production of high-quality and efficient components.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP