Search

What is the main steps to make a plastic injection mold?

- Jul 27,2023

-

Share

Plastic injection molding is a widely used manufacturing process that enables the production of intricate and precise plastic parts. At the heart of this process lies the creation of a plastic injection mold. In the following, we will explore the main steps involved in making a plastic injection mold.

Step 1: Designing the Mold

The first step in creating a plastic injection mold is to design it. This involves careful consideration of the part's geometry, material properties, and production requirements. Skilled designers utilize computer-aided design (CAD) software to create a 3D model of the mold, ensuring that it meets the desired specifications.

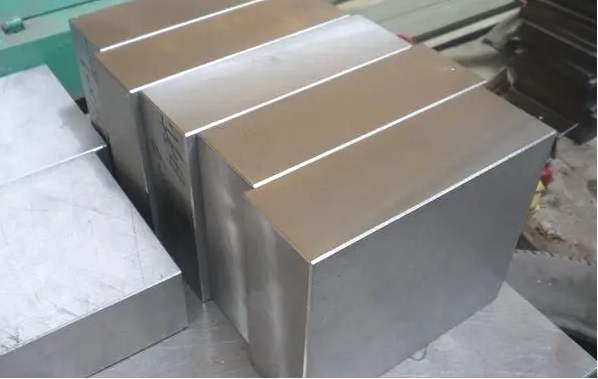

Step 2: Material Selection

Choosing the right material for the mold is crucial. Typically, molds are made from high-quality steel or aluminum alloys due to their durability and heat resistance. The material selection depends on factors such as the expected production volume, part complexity, and budget constraints.

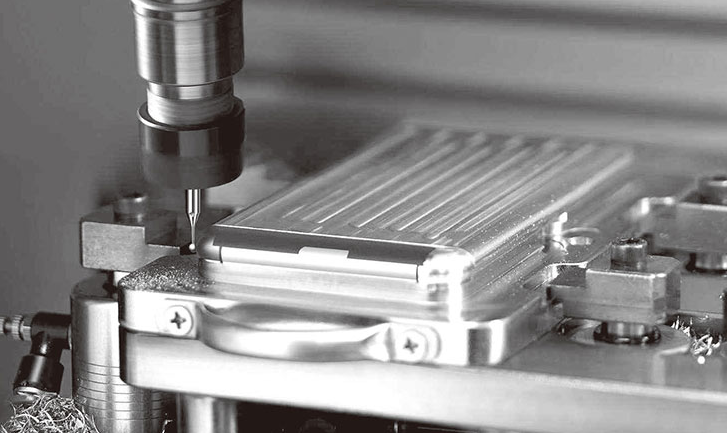

Step 3: Mold Fabrication

Once the mold design is finalized, the fabrication process begins. This step involves several sub-steps, including mold base preparation, cavity and core machining, and the creation of cooling channels. Skilled toolmakers use precision machinery, such as CNC mills and lathes, to shape the mold components with utmost accuracy.

Step 4: Surface Treatment

To enhance the mold's durability and performance, surface treatment techniques are employed. Processes like polishing, texturing, and coating are applied to the mold surfaces. Polishing ensures a smooth finish, while texturing adds specific patterns or textures to the molded part. Coatings, such as nitriding or chrome plating, provide wear resistance and prolong the mold's lifespan.

Step 5: Mold Assembly and Testing

After the individual mold components are fabricated and treated, they are assembled into a complete mold. This involves fitting the cavity and core together, incorporating the cooling system, and attaching any necessary ejector pins or slides. Once assembled, the mold undergoes rigorous testing to ensure proper functionality, including checks for dimensional accuracy, part ejection, and cooling efficiency.

The process of making a plastic injection mold involves several crucial steps, from design and material selection to fabrication, surface treatment, and final assembly. Each step requires expertise and precision to create a mold that meets the desired specifications and ensures high-quality plastic parts. By understanding these main steps, manufacturers can optimize their mold-making process and achieve efficient and reliable plastic injection molding production.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP