Search

What's PCBA? What’s its application?

- Nov 29,2023

-

Share

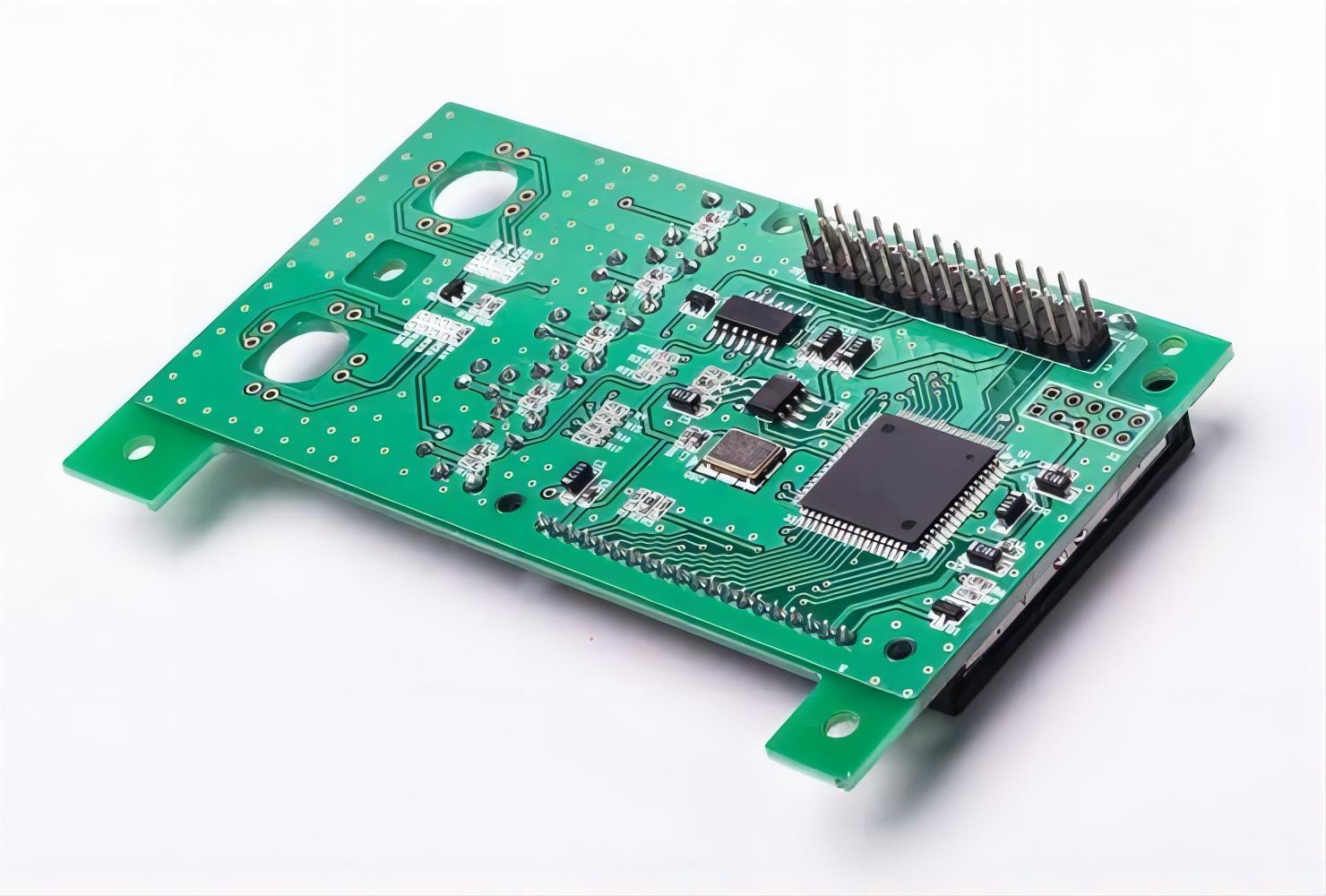

Printed Circuit Board Assembly (PCBA) is a critical process in the electronics industry, playing a pivotal role in the production, prototyping, and maintenance of a wide variety of electronic devices. The acronym "PCBA" refers to the process of assembling electronic components onto a printed circuit board (PCB). This intricate process involves soldering the components onto the board, a task that can be executed either manually or with the aid of automated machinery.

The applications of PCBA are extensive and diverse, spanning across a broad spectrum of electronic devices. From commonplace consumer electronics such as calculators and remote controls to sophisticated industrial equipment and life-saving medical devices, PCBAs serve as the backbone of nearly all electronic devices. They facilitate the crucial electrical connections between components, thereby enabling the seamless functioning of the device as intended.

In the realm of electronic product manufacturing, PCBA is indispensable. Once the design of the PCB is finalized, the PCBA process enables the efficient and reliable assembly of electronic components onto the board. This is particularly vital for the mass production of electronic devices, ensuring consistency and quality in the assembly process, thereby contributing to the overall reliability and performance of the end product.

Moreover, PCBAs are instrumental in the prototyping and development of new electronic products. Through the utilization of PCBA services, designers and engineers can swiftly and cost-effectively produce prototypes of their electronic devices. This empowers them to rigorously test and refine their designs before transitioning into full-scale production, ultimately leading to the creation of high-quality, reliable electronic products.

PCBA is an indispensable process in the electronics industry, with its applications being diverse and essential to the seamless functioning of modern technology. Its significance in the production, prototyping, and maintenance of electronic devices cannot be overstated, making it a cornerstone of the electronics manufacturing landscape.

Let’s talk! We’ll provide the perfect solution for you!

-

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production.

Tripath International is a Canadian company with offices and manufacturing facilities in Canada and China to provide global-scale offerings in Industrial Design, Engineering, Supply Chain, and Manufacturing services, and the ability to convert your concepts into volume production. - Core services — PCBA Design & Manufacturing — Product Manufacturing — Product Structure Design — Plastic & Metal 3D Model Printing — Mold Design — Mold Manufacture — Surface Finishing — Testing

- Technology — PCBA Design And Manufacture — Plastic Injection Molding — Plastic Extrusion — Aluminum Die Casting — Laser Cutting And Welding — Mold Processing — Surface Finishing Technology

- Testing — Product dimension test — Product Rohs environmental test — Flame retardant test — Surface roughness test — Tensile strength test — Metal element test — Wear resistance test — Hardness test — Salt spray test — Low & high temperature aging test — Water proof test — Battery cycle test — Temperature rise test

- Copyright © 2025 Tripath International Inc. All Rights Reserved.

- Design By BONTOP